Hello everybody out there.DCC175_repair AdV.pdf (1.5 MB)

I’m a new patron of the DCC museum and first time user of this forum. I’ve owned my DCC175 and DCC600 since new and have enjoyed both enormously over the years. My 600 in in untouched condition and working perfectly fine apart from occasionally needing a light tap on the tray to open the cassette compartment (maybe known issue and eventually leading to problems?).

This topic is about my DCC175 of which I have replaced the belt successfully in 2016 thanks to an instruction video on YouTube (if I recall correctly in French).

Recently it starting playing up again. The symptoms: after inserting a dcc and pressing PLAY/SIDE it would show normal messages in the display, but wouldn’t produce any sound. You could hear the motor whirr for a few seconds, it would switch to side B, same whirring for a few seconds and would shut itself off. Although it’s four years ago, I believe I had the same symptoms then, so I decided the replace the belt again.

Opening up to the point where you can replace the belt was not too hard. First point of doubt arose here: the belt didn’t look that bad and spinning the motor pulley drove all the little pulleys seemingly without issue. But being at this point and having a spare belt in my drawer I decided to simply replace it anyway. Second point of doubt: the new belt (I ordered 2 in 2016) is in unloaded condition about 2/3 of the length of the old one. Did the old one stretch that much? The new one does fit, but seems to be under quite high tension, maybe too high tension? How great are the chances that having ordered 2 belts a mistake was made and of of the two is actually incorrect? Very small, I’d say, but a little nagging doubt still there.

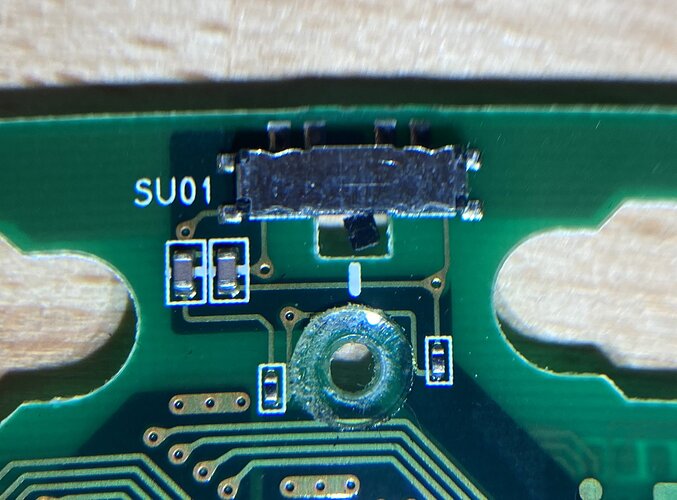

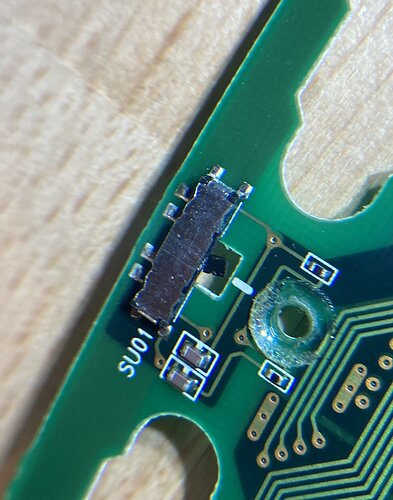

Next bit of doubt - the A-B side switch position. From my first belt replacement I made experience the hard way, having to reopen and toggle the switch to get it to working again. Last time I had to switch the from L to R (or the other way around, cannot remember). This time on opening the switch was in the middle position. Confusion… I thought there were only two positions for this switch. Maybe it stopped working because the A-B switch is in an undefined position. Anyway, to keep a long story short I rebuilt the player 3 times (sigh) with the switch in all possible positions (attached picture tells the process I followed in more detail), but couldn’t get it back to life. In the two first positions (L and R) I was getting some message, from recollection something like ---------PLAY--------- (not something I believe I’ve ever seen before) and after the third rebuild with the switch back in the middle it only shows a blinking cursor in the left upper position of the display. In all instances there was some whirring and clicking/switching/mechanical noise coming from the machine which stopped after 30 secs or so.

Next point of potential concern: alignment of the cassette identification switches (the ones needing unsoldering when getting to the belt) is less than ideal (see attached pictures - apologies for poor picture quality, hopefully the essence is visable).

To top it off… I tried to run the service setting mode. Have tried many times, but it will not go into this mode. All I’m getting is the blinking cursor again and motor whirring.

If anyone has any suggestions what I could try as a next step would be greatly appreciated.