Dear All,

Upfront, as always a big thanks for your support and feedback. I really appreciate this community!

After successfully replacing the belt on my DCC 175 I wanted to have a DCC 170 as well ![]() .

.

Once I managed to buy a DCC 170, my tests revealed that the motor is humming but no display is shown. The solution in most cases can be found in replacing the belt like I did for the DCC 175. So all went pretty okay until I added the new belt…

On this DCC 170 I removed the two PCB boards to finally reach the motor, belt and gears section. The old belt was pretty warn-out so I removed it. I first cleaned all the belt wheels (three copper/metal wheels and one black plastic one) with IPA to remove remaining rubber/grease. Then I placed the new belt which fitted fine.

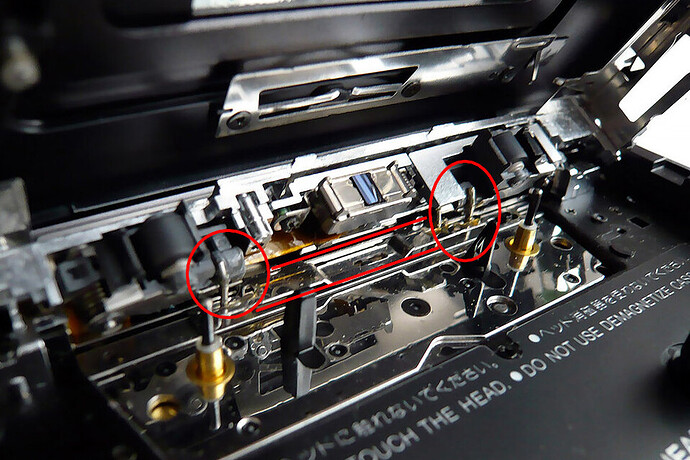

So far so good… but then during manual turn tests, to check the belt’s position by switching the black lever a few times, I noticed that it works fine until the black gear’s area (highlighted by red circle) reaches the black lever position (green arrow). Then the belt starts slipping and the blue circled switch lever will not change its position. For other two black gear wheel areas/positions this is not a problem and the blue circled switch lever nicely change its position, except for the red circled area.

To overcome this I tried some grease/silicon spray on each of the wheels and gears, but still no luck. the belt seems to be okay, not to wide/tight. So any idea what causes this behavior? Seems like once the black gearwheel turns to the red circled area angle, it delivers some resistance with the black lever and as a results the belt starts slipping. At this point it is not blocked as, with some manual help, it can complete its turn resulting in the blue circled lever to change its position. Please see picture (taken from internet to clarify) below to explain the issue according colored circles and arrow.

I hope I explained it well enough for you guys to understand as it is difficult to write down the exact issue.

Regards,

John (Lee Fang)